Venture Funding for New, “University Bred” Medical Technologies: When It’s Time and What to Bring

If you’ve been following our funding series for innovators seeking to spin out new medical technologies from higher ed “environments”…

As of November 30, 2023 T3 Labs is Part of Veranex. Click Here to learn more.

GCMI Design & Development has moved to gcmiatl.org

Design verification and validation is often completed through physical testing, but can also include other methods such as inspections, review of specifications, or analysis of materials.

Section 21 CFR 820.3 of the federal code defines design verification as “the process of confirmation by examination and provision of objective evidence that specified requirements have been fulfilled.” Design validation is defined as “the process of establishing by objective evidence that product specifications conform with user needs and intended use(s).”

The goal of verification is to ensure there is sufficient evidence that a new medical technology or device has met all engineering requirements (design inputs). Design validation ensures the product’s design output meets identified user needs. User needs can be validated in different ways including usability studies, short or long preclinical studies, and clinical trials. These typically evaluate the user’s interaction with the device, or its comprehensive functional performance.

A user need may state that the device must be portable. The validation test will confirm that a typical end user is capable of moving the product with them while doing certain daily activities.

A cardiac catheter may be required to detect electrical signals in the heart. A validation test may include recording electrical signals from a pig heart.

If an orthopedic device needs to stabilize a fracture, a validation test may be to implant the product in a pre-clinical model of a bone break and monitor displacement over time.

A user need may indicate that a clinician must be able to dispense medication from a device. To validate the design, a usability study may demonstrate that a typical user can make selections from a touch screen in order to open a dispensing drawer.

Our preclinical program director Evan Goldberg shared the following:

Preclinical work would enter verification and validation testing very early in the design and development process for a resorbable material, implant or FDA Class III device given the need to see how the device or technology performs in a chronic survival animal for a period of time. This is required to verify and validate engineering requirements and that the product meets clinical needs.

Preclinical work would enter verification activities later in the design and development process for non-implantable products or technologies like surgical instruments that can [employ bench testing for a significant portion of verification and validation testing requirements]. Preclinical work later in the process assesses performance and human factors that can only be validated in a preclinical model, either cadaveric or in vivo.

GCMI and our preclinical arm T3 Labs have successfully completed verification and validation testing for medical technology innovators from industry giants like Abbott and Boston Scientific to early and growth stage companies like ALung Technologies to physician innovators and engineers like Dr. Rebecca Levit, Professor Christopher Saldana and many others.

If you would like to take a deeper dive into our verification and validation testing capabilities for your new medical technology, product or device please use the contact form below. We will put you in touch with the member of the team most appropriate to address your needs.

Medical Device Innovation: A one-on-one with ATDC Lead Entrepreneur in Residence Frank Tighe and GCMI CEO Tiffany Wilson

Tiffany Wilson, GCMI CEO, and Frank Tighe, Lead Entrepreneur in Residence at ATDC, discussed the medical product development process for early stage innovators. Learn from their experiences by watching.

When an innovator has identified a medical problem, taking an efficient approach to identify the viability of potential solutions is key. Feasibility focuses on evaluating critical product elements early.

At the completion of this phase, an innovator will have data-based support for the value in launching a full development program for the product including needed medical device design services.

In our experience, careful planning streamlines medical device design services needs and the product development process, lowering costs and providing greater market predictability.

At the completion of this phase, the project team will have a clear vision for the path to generating the product.

Iterations from medical device design services, refinement and evaluation allow for product evolution from the prototype stage to manufacturable assembly.

At the completion of this phase, the project team will have the specifications and initial supporting test data for a functional product.

Thorough engineering evaluations of the product demonstrate whether the output of medical device design services and efforts have met all of the product requirements.

At the completion of this phase, a project team will have statistically significant evidence of the product’s functionality and safety.

Thorough system and user testing demonstrate whether the design has sufficiently addressed the customer’s clinical need.

At the completion of this phase, a project team will have documented evidence as to whether the product is usable and solves the stated clinical need.

In order to scale production to quantities needed for sale, manufacturing processes must be shown to repeatedly and reliably generate the commercialized product. For many medical products, regulatory approval must also be granted prior to market introduction.

At the completion of this phase, the product will be ready for routine production and sale.

We call this “Phase 0.” During these early stages, we help guide products to the most efficient and effective pathway by using evidence-based decisions for product development.

We have a staff that brings engineering skills, close attention to detail and a commitment to the development process. They have the insights to lead you down a more cost-efficient pathway to regulatory submission, manufacturing and commercialization.

Our staff includes a Medical Affairs Liaison who provides and gathers initial voice of customer inputs at the earliest stages of a project, and adds guidance and perspective throughout the later stages.

Your success is our goal, so we treat your projects like our own. Our goal is to move through the development process in the right way. We guide our projects along a particular path because we know the risks.

Our team is filled with biomedical and mechanical engineering talent, including professionals with biomedical and/or mechanical engineering degrees. We are well versed in the tools and methods to make a medical product.

Where does preclinical testing enter the design and development phase of new medical technologies and devices? GCMI Design and Development Director Mike Fisher and Preclinical Program Director Evan Goldberg share deep dive insights.

“At the end of the day, some testing requirements in the design and development phase simply cannot be done ‘on the bench,’ Evan says. “In design input requirements and confirmation activities within the design and development phase, only cadaveric or small scale in-vivo testing can determine if a device provides appropriate grip or traction for the user, or if it works as intended in a beating heart or vessels with blood flow. Read on.

How can medtech, life science and biopharma innovators know their product is ready for preclinical testing? GCMI Design and Development Director Mike Fisher and Preclinical Program Director Evan Goldberg joined Renovo Biomedical’s Anna Fallon on January 14, 2021 to answer that question.

“How quickly can you get your feasibility study to look like your GLP study? When you’re doing any level of pre-GLP preclinical studies, you have to maximize the value of the information you are getting. You never want to go into verification and validation testing without knowing the answer to your questions.” Access the recording here.

Design validation ensures that you have made the “right” product – according to the customer’s needs. Design verification ensures that the team has made the product “right” – according to regulatory and engineering requirements.

How does verification and validation in the design and development process “translate” to preclinical?

Find the insights from GCMI / T3 Labs Preclinical Program Director Evan Goldberg tells us in this Q&A. Read more.

At the completion of the design phase, a product will have well-defined design inputs, plus fully described design features and manufacturing methods. Design verification and validation then takes this design output (product) and ensures that it meets all engineering requirements and user needs, respectively.

Have you made the right product? Have you made the product right? Read more about GCMI’s approach to medical device design verification and validation.

Medtech innovation is an exciting, yet risky enterprise. The vast majority of venture capital and strategic investors now want to see early investment in de-risking medical innovations. There is simply too much potential for failure in the pathway to commercialization, plus financial risk related to market forces and competitive products.

Too many medtech development projects are unsuccessful because innovators discover major roadblocks too late in the process. Here are some of the top ways to give your medtech innovation a better chance for successful commercialization.

Designing for manufacturability is a critical task. The effort to develop a component manufacturing process and an assembly process is just as critical. Making these two paths overlap as much as possible allows a development team time to improve on manufacturing methods prior to any pilot builds.

IEEE 11073-20701™-2018 defines an architecture that binds the participant and communication model to the Web services data transport model defined in previous IEEE 11073™ standards.

PISCATAWAY, NJ, 14 Feb. 2019 – IEEE, the world’s largest technical professional organization dedicated to advancing technology for humanity, and the IEEE Standards Association (IEEE SA), today announced the publishing and availability of IEEE 11073-20701-2018 – IEEE Approved Draft Standard for Service-Oriented Medical Device Exchange Architecture & Protocol Binding.

If you’ve been following our funding series for innovators seeking to spin out new medical technologies from higher ed “environments”…

In part 1 of our 2023 State of Medtech Design and Development Report we discussed sensors, AI and the paradigm…

You’re a university-based researcher, investigator, faculty member or perhaps even a student who has snagged your first funding for the…

Innovation in medical technologies is something of a paradox. On one hand, new technologies that drive innovation can manifest at…

Innovation in pediatric technologies that address unmet clinical needs lags behind innovation for adult populations in large part due to…

Lumbar punctures are a procedure performed by neurologists to obtain cerebrospinal fluid from a patient’s back, typically from the L3/L4…

GCMI’s Spring 2023 Capstone Spotlight on Team LifeSTEM “Gliomas are brain tumors that come in multiple forms ranging from low-grade,…

Revolutionizing Pediatrics: Innovations in Medical Device Design & Development. A Pediatric Tech Talk Webinar with GCMI, June 21, 2023 –…

“X-rays supporting our testing at GCMI and T3 Labs clearly showed where the device engaged and the tip aligned at…

Medtech startups or established businesses looking to scale are encouraged to apply for one of the upcoming 16-week accelerator cohorts…

Funding varies in specific levels from fiscal year to fiscal year, specifically supports projects with high potential for successful commercialization,…

A “Catheter Gripping Tool” solving an unmet need as GCMI’s grows its roster of collaborative medtech innovations with the Children’s…

GCMI, a non-profit affiliate of the Georgia Institute of Technology, is actively recruiting for a research engineer to lead multiple…

“Because we followed a solid pathway, we had a lot more latitude to make positive changes that should increase the…

Quick Insights Aligned in Acceleration: Indeed, the Most Expensive Preclinical Study is the One You Have to Do Twice As…

The phrase “personalized medicine” has been thrown about by so many for so long in healthcare as to defy definition:…

So many engineers probably wanted to be an astronaut as kids at some point or another. Saylan Lukas wanted to…

“In partnership with Georgia CTSA (Clinical and Translational Science Alliance), the I3 (Imagine, Innovate, and Impact) GCMI Research Awards are…

The team’s work to date, from concept to the technology’s current state, had primed it to seize the opportunity presented…

“When your ‘north star’ is doing what’s right for the patient and the user, everything else can follow. The best…

Medical technology innovation and critical supporting service providers are not only working through pent up demand for delayed projects from…

Founded by Cardiologists In the late 1990s, Dr. Robert Matheny, Chief Scientific Officer of CorMatrix Cardiovascular Inc., was looking for…

As industries of all shapes and sizes continue to evolve embracing remote work models and various levels of return to…

“The failure of existing products on the market to successfully accomplish the needs of patients and clinicians made this a…

“I can say with confidence our journey toward commercialization of our new [wearable pediatric stethoscope] medical technology would have taken…

Investigational Device Exemptions are required by the U.S. FDA for devices or technologies that require clinical use before regulatory approval…

Congratulations are in order! GCMI Chief Executive Officer, Sherry Farrugia, and Director for Product Development Mike Fisher, were among those…

Our colleagues at Southeast Life Sciences are now accepting applications for Pitchrounds at AdvanSE 2022. They’re seeking the southeast’s…

Learn from our experience to streamline your regulatory pathway and set your new medical device or technology up for commercialization…

New medical technologies or devices cannot enter stages of research or clinical trials in humans without certain authorizations required by…

In 2014, a Children’s Healthcare of Atlanta nurse, Lynn Pogue, approached an engineer, Leanne West from Georgia Tech, to discuss…

According to the American Red Cross, every two seconds someone in the United States needs a blood transfusion. That fails…

A team of mechanical, electrical and computing engineers, supported by the Director of Cardiac Intensive Care for Children’s Healthcare of…

How we walk is a key indicator of any injury, recovery pathway and overall health. Clinicians’ analysis for assessment of…

Once a new medical technology or device is ready to go from prototype to product, following a defined process and…

A medtech or life science project’s success is dependent on the careful consideration of several intersecting components: technological, clinical, commercial…

When it comes to medtech innovation, our client’s success is always our top priority. We help find the right people…

The Fluid Fighters Capstone team needed to test their prototype for draining rates and tissue adherence or occlusion avoidance. GCMI’s…

Yoel Alperin, Parth Gami, Sindhu Kannappan and Kelly Qiu comprise the Georgia Tech Spring 2021 Capstone Design Team ScolAlign. Their…

GCMI is now pleased to offer you a deep-dive, behind-the-scenes look at what we do and how we do it…

“Our validation work would not have been possible without GCMI’s support and T3 Labs’ facility and equipment. Being ‘radio-opaque’ is…

“We needed to validate whether or not our device could create the appropriate pressures needed to restore esophageal function in…

Georgia Bio, the state’s life science trade association, named GCMI, the Saldana Research Group and Georgia Tech 2021 Golden Helix…

In the context of GCMI’s phase-gated product development, the “Design and Development” phase (also called “Phase 2” at GCMI) typically…

There are approximately 292,000 cases of in-hospital cardiac arrest every year for which the survival rate is less than 24…

Where does preclinical work find its way into project planning for new medical technologies? What are the top considerations for…

Georgia Tech recently completed its Fall 2020 (virtual) Capstone Design Expo. From the project’s website, “The Capstone Design Expo showcases…

Last month, Georgia Tech named Raghupathy “Siva” Sivakumar inaugural Interim Chief Commercialization Officer. From Georgia Tech Research Horizons: “Sivakumar…

How does medtech design verification and validation “translate” to preclinical testing? GCMI’s Director of Scientific Affairs explains.

Preclinical evaluations are often the best way to assess a medical product’s performance, and regulatory bodies often require preclinical data…

Watch, listen and learn. Our 2020 AdvanSE session can help you know, and fix, the ways medtech innovators burn cash…

Medtech and life science innovation is a complex, costly endeavor. How do you know you are on the right regulatory…

Innovative medical technologies start with a great idea, novel science and an identified unmet clinical need. The process by which…

From our colleagues at the Children’s Healthcare of Atlanta Pediatric Technology Center – “We knew that we had an innovative…

Overheating lighting instruments coupled with human error are a leading cause of intraoperative fires and patient burns. The healthcare system…

At the end of verification and validation, a medical product is ready for regulatory submission or marketing, depending on the…

All types of innovators need to carefully protect their intellectual property (IP) from those who may infringe on their ideas…

The vast majority of novel ideas from academia never make it into clinical use. Together we can change that. Innovative…

A significant number of innovative medical technologies fall into FDA’s Class II classification, the vast majority of which require an…

Medical product design verification and validation activities (called “Phase 3” and “Phase 4” at GCMI) typically come after a design…

Design and Development for medtech: digging in to complete design tasks, achieving design freeze and ensuring readiness for manufacturing.

GCMI helps medtech innovators, including physicians, academic researchers and professors, startups and large strategic companies, bring their products to market.…

Following closely on the heels of GCMI’s work with Georgia Tech and others to design, produce and deliver hundreds of…

Where does Medtech Project Planning fit in with Product Development and why is it important? Let’s review the basic steps…

Tiffany Wilson, CEO of The Global Center for Medical Innovation (GCMI), and Frank Tighe, Lead Entrepreneur in Residence at The…

Friends and colleagues, we hope you will enjoy this inspiring story of innovation and collaboration that is helping keep our…

The design and development process can make or break a medical device’s commercial potential. It is dependent on careful consideration…

Medtech innovation is an exciting, yet risky enterprise. The vast majority of venture capital and strategic investors now want to…

As the global COVID-19 pandemic continues to force all of us to find safe paths forward, GCMI continues to remain…

In mid-March 2020, the shortage of personal protective equipment for healthcare providers responding to the COVID-19 outbreak had become a…

Aflac Incorporated, a leader in supplemental insurance at U.S. worksites, today announced it has contributed $5 million to two organizations that are…

In one week, a team of students in a joint biotech medical lab with Georgia Tech and Emory students started…

From the Delta News Hub: April 2, 2020: Delta Flight Products, the airline’s wholly owned subsidiary, is collaborating with Global…

“In response to the unprecedented challenges from the COVID-19 pandemic, ExxonMobil is applying its deep knowledge and experience with polymer-based…

To our GCMI clients, experts, and friends – From the beginning of the COVID-19 crisis, my team and I have…

Earlier today Medical Design & Outsourcing published the following from the FDA regarding 3D printed equipment intended to supplement PPE…

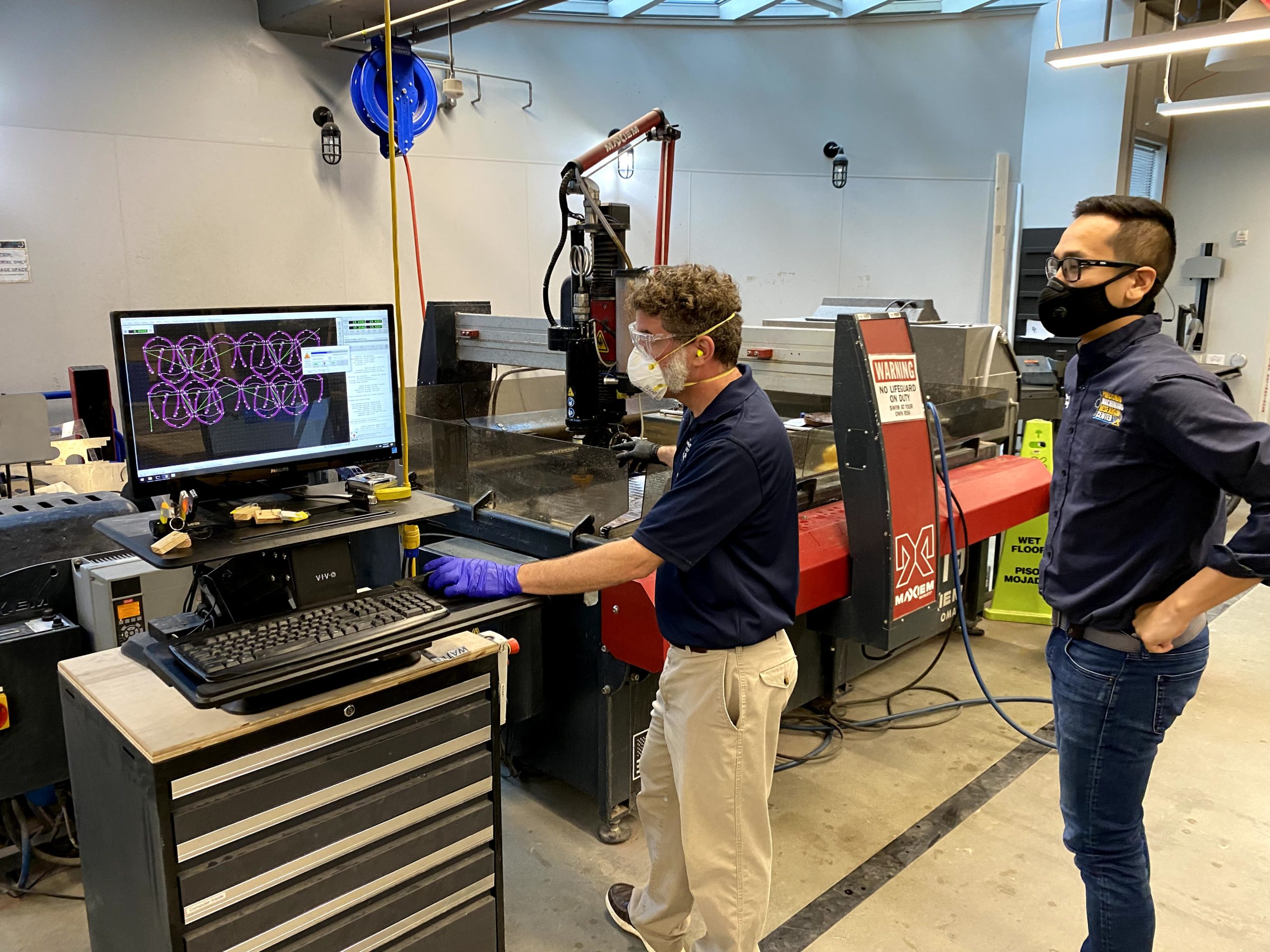

Research Collaboration to Allow Manufacturers to 3D Print Thousands of Face Shields in the Coming Weeks Atlanta, GA –…

Image credit: GT Research Horizons GCMI, in partnership with Children’s Healthcare of Atlanta and the Georgia Tech Pediatric Technology…

We are pleased to partner with Dr. Joanna Newton, along with a skilled and motivated team at Georgia Tech and…

Fast track answers to critical questions that de-risk medtech innovations When an innovator has identified a medical problem, taking…

Prototyping is an exciting and important part of the medical product innovation process. Prototypes can give you something tangible to…

Photo courtesy of http://studyclerk.com/ For most medical device innovators, prototyping is one of the most exciting times in product development.…

GCMI’s Sarah Cohen and Mike Fisher provided substantial insights for Assembly Magazine’s Austin Weber in a recent article, “Best Practices…

As the year comes to a close and many of us look forward to a holiday respite, I find myself…

GCMI’s foremost goal as an affiliate of the Georgia Institute of Technology is to partner with Georgia Tech faculty and…

At GCMI, medtech and medical device innovation are at the core of our efforts including our work within our industry…

GCMI’s 2018 year end review and 2019 look ahead Thanks to our staff, customers, sponsors and fellow industry, academic…

So you have an idea for a new medical device. Now what? Coming up with a concept for a new…

In GCMI’s experience, the decision to commit to a design and development plan for a new medical product should not…

In medical product development, correctly identifying and committing to your FDA approval process or pathway can make or break many…

Michael Fisher, Director of Product Development for GCMI, shares his insights from the IEEE-NIH Healthcare Innovations and Point of Care…

Medical technology innovators learn quickly that there is little, if any, flexibility in the FDA approval process. NFANT Labs knew…

“Children aren’t little adults, yet we expect our physicians to retrofit adult devices to fit a pediatric patient,” says Sherry…

GCMI’s Director of Product Development, Mike Fisher, recently spoke about the ins and outs of successful medical device development as…

Connect with GCMI and T3 Labs at GSACS 2017! The Georgia Society of the American College of Surgeons (GSACS)…

Who better to address unmet clinical needs and life-changing improvements to medical devices of all types than clinicians themselves? Piedmont…

The 2017 edition of the Southeastern Medical Device Association (SEMDA) annual conference has come and gone, and this year was…

Micro C raises additional $700K in seed round to complete several planned initiatives and bring their novel medical device…

GCMI and T3 Labs CEO Tiffany Wilson shares insights with Assembly Magazine on what it takes to bring a medical…

Having a facility like T3 to test novel and breakthrough applications’ ability to save lives is crucial for battling diseases…

GCMI and T3 Labs CEO Tiffany Wilson shares medtech development pathway insights in Medical Product Outsourcing. Bringing a new…

The Masters of Biomedical Innovation and Development program (BioID program) is a collaborative academic experience in Biomedical technology and a…

Dr. Steven Goudy, MD, is an associate professor and Director of Pediatric Otolaryngology for the Emory School of Medicine. He…

Innovators seeking to enter the world of medtech face a daunting path from concept to commercialization. Design, engineering, prototyping and…

Now more than ever, physician innovators are entering into a highly regulated and cost constrained environment. “This industry is not…

Read how GCMI and T3 worked together to help John Erbey at Strataca develop a new way to manage Acute…

At T3 Labs, we take great pride in our scientific acumen. Afterall, the organization was conceived and designed by translational…

Preclinical medical device testing: how do you know you are ready and how do you make the most efficient investment…