Lateral access has become the preferred, minimally invasive method for lumbar spinal surgery. Entering the torso from the side significantly shortens patient recovery times and lessens tissue trauma thanks to a smaller incision requirement.

Thorough surgical training programs are required to ensure physicians avoid localized damage to nerves in the pathway between the incision site and the spine. This type of training is typically done in cadavers, which limits the procedure’s availability. In many parts of the world, like Latin America, cadaver labs are few and far between or non-existent.

What is needed is an anatomically precise synthetic model, built to perform properly at room temperature throughout its lifecycle, to properly train physicians on the procedure so more patients worldwide can benefit from lateral access spinal surgery. While the technology does exist (pioneered by the Mayo Clinic in Jacksonville, Fl.), production costs are high and volume capability is low.

Enter the Georgia Tech Spring 2021 Capstone Design Team “Vertebros.” The team of Beau Bruneau, Michael Pullen, Suraj Rajendran and Vishal Shah enlisted GCMI’s Evan Goldberg for the background on cadaveric tissues and synthetic materials that might most closely meet the project’s needs including 3D printing opportunities and cost reduction.

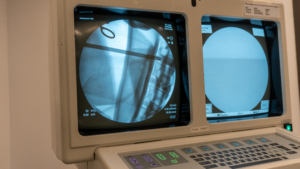

Their model design and build work complete, the team used the operating room at GCMI’s preclinical testing and bioskills training arm, T3 Labs, to validate the model’s radio opacity and neuro stimulation mapping tool.

“Our validation work would not have been possible without GCMI’s support and T3 Labs’ facility and equipment,” Pullen told us. “Being ‘radio-opaque’ is a critical design input for this tool. That type of feedback is impossible without a proper operating room environment. Thanks to the opportunity to use the OR at T3 Labs, we did indeed validate the appropriateness of our model’s tissue with respect to scalpels, retractors and laparoscopic devices. It was precisely the near real life feedback we needed to help make this training tool, and ultimately lateral access spinal surgery, available to more of the world’s surgeons and their patients.”

Beyond validation, what did the team learn?

“Biomedical engineering is difficult, even for high achieving students and professionals,” Pullen said. “It’s OK to get frustrated, anxious or upset. You are not alone in this experience. When you acknowledge that, it becomes possible to get out of your comfort zone and try something new. Take chances. Make mistakes early. Work on challenging, innovative projects that give you great learning opportunities and build your resume in a way employers appreciate even if those projects don’t work out as you might have hoped.”

GCMI is proud to support our colleagues and students at Georgia Tech. We congratulate the Vertebros team on their efforts and wish each member great success in their future endeavors. You can watch their presentation here.

GCMI’s mission is to bring new medical technologies to market that improve quality-based outcomes and delivery of care for patients worldwide. This certainly includes supporting development of medical technologies born in our backyard from faculty, researchers and students with whom we share our institutional affiliation. We congratulate the Spring 2021 teams and eagerly anticipate what the Fall 2021 teams have to show us later this year.